Cavitation can cause a number of problems for pumps, including:

* Noise and vibration

* Reduced efficiency

* Damage to the impeller blades

To prevent cavitation, it is important to ensure that the pump is operating within its recommended operating conditions. This includes using the correct impeller size and speed, and avoiding high inlet temperatures and pressures. In some cases, it may also be necessary to use cavitation-resistant materials for the impeller blades.

Here is a more detailed explanation of the process of cavitation in impeller pumps:

1. As the impeller blades rotate, they create a low-pressure region behind them.

2. If the pressure in this region falls below the vapor pressure of the liquid, the liquid will start to vaporize.

3. The vapor bubbles will then collapse when they come into contact with a higher-pressure region.

4. This collapse creates shock waves that can damage the impeller blades.

Cavitation can also cause a reduction in pump efficiency. This is because the vapor bubbles can interfere with the flow of liquid through the pump, reducing the amount of work that the pump can perform.

In addition to noise, vibration, and reduced efficiency, cavitation can also lead to damage to the impeller blades. The shock waves created by the collapse of the vapor bubbles can cause the blades to erode and crack. This can eventually lead to the failure of the impeller.

To prevent cavitation, it is important to ensure that the pump is operating within its recommended operating conditions. This includes using the correct impeller size and speed, and avoiding high inlet temperatures and pressures. In some cases, it may also be necessary to use cavitation-resistant materials for the impeller blades.

By following these guidelines, you can help to prevent cavitation and extend the life of your impeller pump.

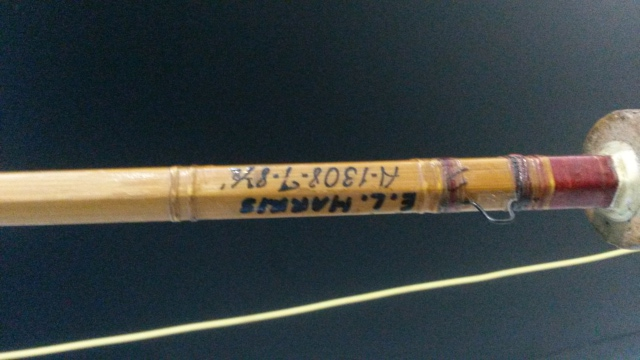

Shakespeare bamboo rod identification

The Fishing Tackle Graveyard: What Do You Do With Your Old Gear?

Copyright © www.mycheapnfljerseys.com Outdoor sports All Rights Reserved