With a few specialty tools, turning scrap metal into leadhead jigs is easy and fun and will save you a few bucks to boot.

The first thing you need is lead. There are two types. Soft lead is nearly pure and available at scrap metal dealers. (My local dealer sells it for 35 cents per pound.) Hard lead is less pure and available at most tire shops in the form of wheel weights. Each has its pros and cons: Soft lead is easier to mold into jigheads, especially for smaller sizes. Hard lead is cheaper. (My local tire shop, like most, happily gives lead wheel weights away.)

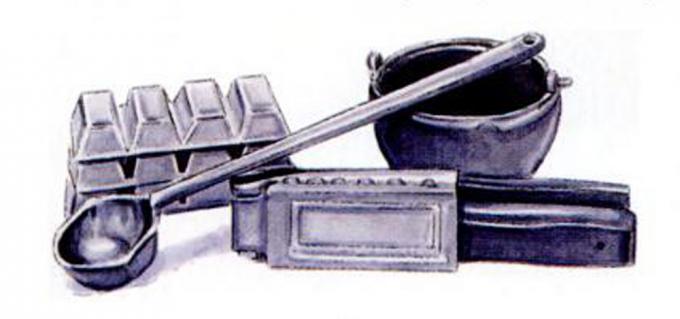

To melt and pour the lead, you need a reliable heat source, such as a stove top, a melting pot, and a ladle. Another good option is a lead furnace. (Just be sure to follow safety precautions provided by manufacturers.)

To turn the melted lead into jigheads, you need a mold. Do-It Jig Molds (www.do-itmolds.com) are widely available and come in almost every conceivable jig style (from basic round-heads to weedless banana jigs). Each mold gives hook specifications and produces between three and 20 jigheads at a time, depending on size and style.

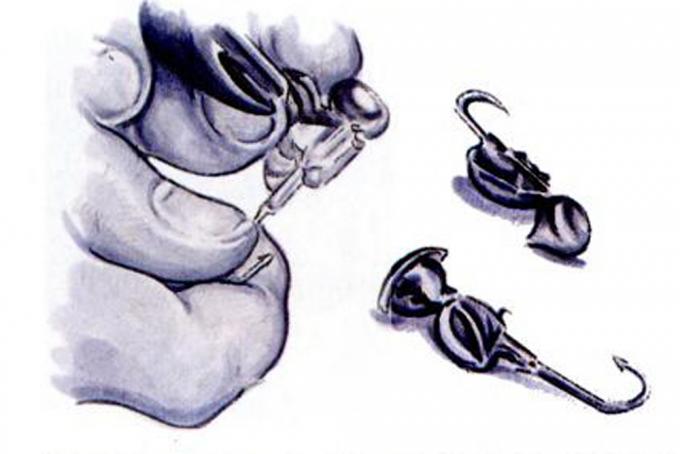

Finally, you need gate shears. Jigheads fresh out of the mold have a "gate" or "sprue" of waste lead. Gate shears nip this off cleanly.

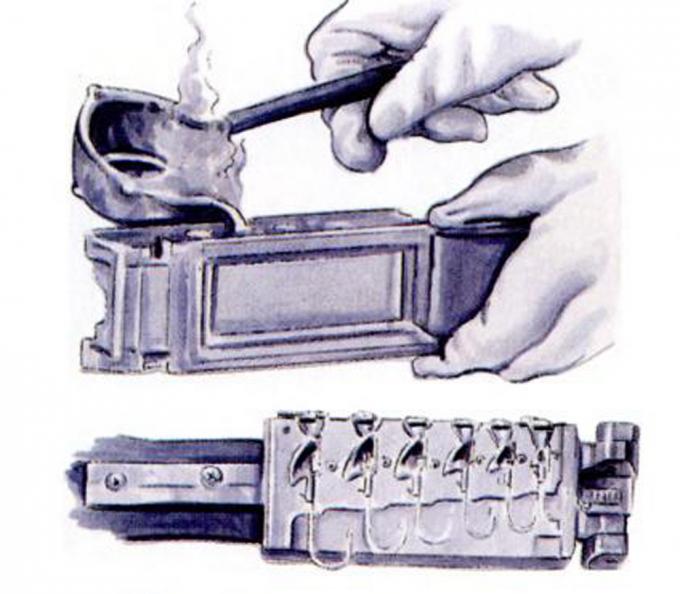

Once you have the tools and materials, the process is almost self-explanatory. Open the mold, place a hook into each jighead cavity, and close the mold. Melt the lead and pour it into the mold cavities. Let it cool, then open the mold, retrieve your jigheads, nip the gate, and you're done.

Before long, you'll have a pile of jigheads--ready to go in the tackle box.

Should You Eat Real Food on the Bike?

How to Catch Trophy Largemouth Bass on Trout Swimbaits

Copyright © www.mycheapnfljerseys.com Outdoor sports All Rights Reserved